The piece of plexi-glass is at the front here. Click the picture for a slightly larger, but much clearer version.

The piece of plexi-glass is at the front here. Click the picture for a slightly larger, but much clearer version. The finished back.

The finished back. The finished front.

The finished front. Finished from above.

Finished from above.Project completed successfully!

D - I - Y

The piece of plexi-glass is at the front here. Click the picture for a slightly larger, but much clearer version.

The piece of plexi-glass is at the front here. Click the picture for a slightly larger, but much clearer version. The finished back.

The finished back. The finished front.

The finished front. Finished from above.

Finished from above. The new schematics. Click picture for a larger version.

The new schematics. Click picture for a larger version. The board with it's components. A heat sink may be added here and there in a later stage.

The board with it's components. A heat sink may be added here and there in a later stage. This is the power supply close to it's current phase. At the moment the board is connected to all front-side controls. The transformer is wired too. Now the board needs to be hooked up to the transformer and the transistors need to be mounted on the heat sink and wired. That will be done soon.

This is the power supply close to it's current phase. At the moment the board is connected to all front-side controls. The transformer is wired too. Now the board needs to be hooked up to the transformer and the transistors need to be mounted on the heat sink and wired. That will be done soon.

Based around the good old 723 voltage regulator.

Based around the good old 723 voltage regulator. The multi meter is also finally paying off :-)

The multi meter is also finally paying off :-) Another close up. Breadboard fun...

Another close up. Breadboard fun...

That big chunk of metal is the transformer. It turns 220V into 24V. It's screwed on to the bottom of the casing. It's 72VA (which is 72W coz voltage (V) x Current (A) = Power (W)).

That big chunk of metal is the transformer. It turns 220V into 24V. It's screwed on to the bottom of the casing. It's 72VA (which is 72W coz voltage (V) x Current (A) = Power (W)). The back and the front panels. The back panel holds the socket for the mains cable and the fuse. ALWAYS use a fuse! For this project I use a 500mA fuse. This only protects the house from a power outage. To protect my equipment I should actually use a fuse of (72/220) 0.3A. I have to see if those actually exist...

The back and the front panels. The back panel holds the socket for the mains cable and the fuse. ALWAYS use a fuse! For this project I use a 500mA fuse. This only protects the house from a power outage. To protect my equipment I should actually use a fuse of (72/220) 0.3A. I have to see if those actually exist... A close-up of the front panel, just because it's a cool photo ;-)

A close-up of the front panel, just because it's a cool photo ;-) This is the front after putting it together...

This is the front after putting it together... ... and this is the back.

... and this is the back. Right, so here's the lamp.

Right, so here's the lamp. And here's the switch. Good thinking huh?

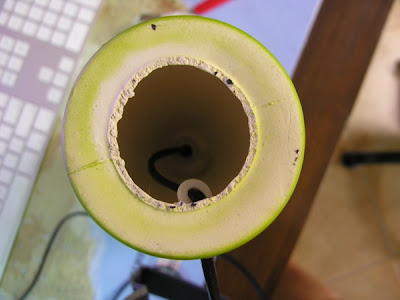

And here's the switch. Good thinking huh? Top view of the lamp.

Top view of the lamp. Bottom view of the lamp.

Bottom view of the lamp. Remove the bottom first. This is ugly, sticky stuff that after removig can only be thrown away (in my case).

Remove the bottom first. This is ugly, sticky stuff that after removig can only be thrown away (in my case). When it's gone there's a nice hole left and we can admire the complicated inside (not).

When it's gone there's a nice hole left and we can admire the complicated inside (not). In the meantime back at the ranch; The Switch.

In the meantime back at the ranch; The Switch. The switch requires a hole to put it in. I bought nice special drill bits that are aparently made for glass and tiles. This is the big one...

The switch requires a hole to put it in. I bought nice special drill bits that are aparently made for glass and tiles. This is the big one... ... and this is the small one. I usually drill holes in 2 stages.

... and this is the small one. I usually drill holes in 2 stages. Drilling. The base of the lamp seemed to be made of clay, hardly baked at all, supersoft. Oh well.

Drilling. The base of the lamp seemed to be made of clay, hardly baked at all, supersoft. Oh well. I made a nice round hole. Ever noticed that when you drill with a metal drill the holes are actually triangular?

I made a nice round hole. Ever noticed that when you drill with a metal drill the holes are actually triangular? To be able to work properly we have to pull out the wires.

To be able to work properly we have to pull out the wires. This is tricky. The cord needs to be cut open. Get some wooden stick and put it through the wire effectively creating a cutting surface. Knowing that there are only 2 wires inside, place a knife in the middle and start cutting the wire open for about 5 cm. Make sure you stay in the middle otherwise you may damage one of the inside wires.

This is tricky. The cord needs to be cut open. Get some wooden stick and put it through the wire effectively creating a cutting surface. Knowing that there are only 2 wires inside, place a knife in the middle and start cutting the wire open for about 5 cm. Make sure you stay in the middle otherwise you may damage one of the inside wires. The result should be something like this.

The result should be something like this. Cut one of the wires in half. It doesn't matter which one because we're working with alternating current (meaning the + and - (ground) change usually 50 times a second (50Hz)).

Cut one of the wires in half. It doesn't matter which one because we're working with alternating current (meaning the + and - (ground) change usually 50 times a second (50Hz)). Strip the ends so that about 5 mm of copper is exposed.

Strip the ends so that about 5 mm of copper is exposed. Twist the ends together nicely so they seem 1 thick wire.

Twist the ends together nicely so they seem 1 thick wire. Put the ends in the switch and fix the wire very tight.

Put the ends in the switch and fix the wire very tight. Put the switch inside the lamp and make it stick out through the hole.

Put the switch inside the lamp and make it stick out through the hole. Put the switch-cover on and it's done!

Put the switch-cover on and it's done!